LibreWater

Developing Free Open Source Hardware Designs for solar-thermal desalination that can be manufactured and innovated locally in Makerspaces across the world.

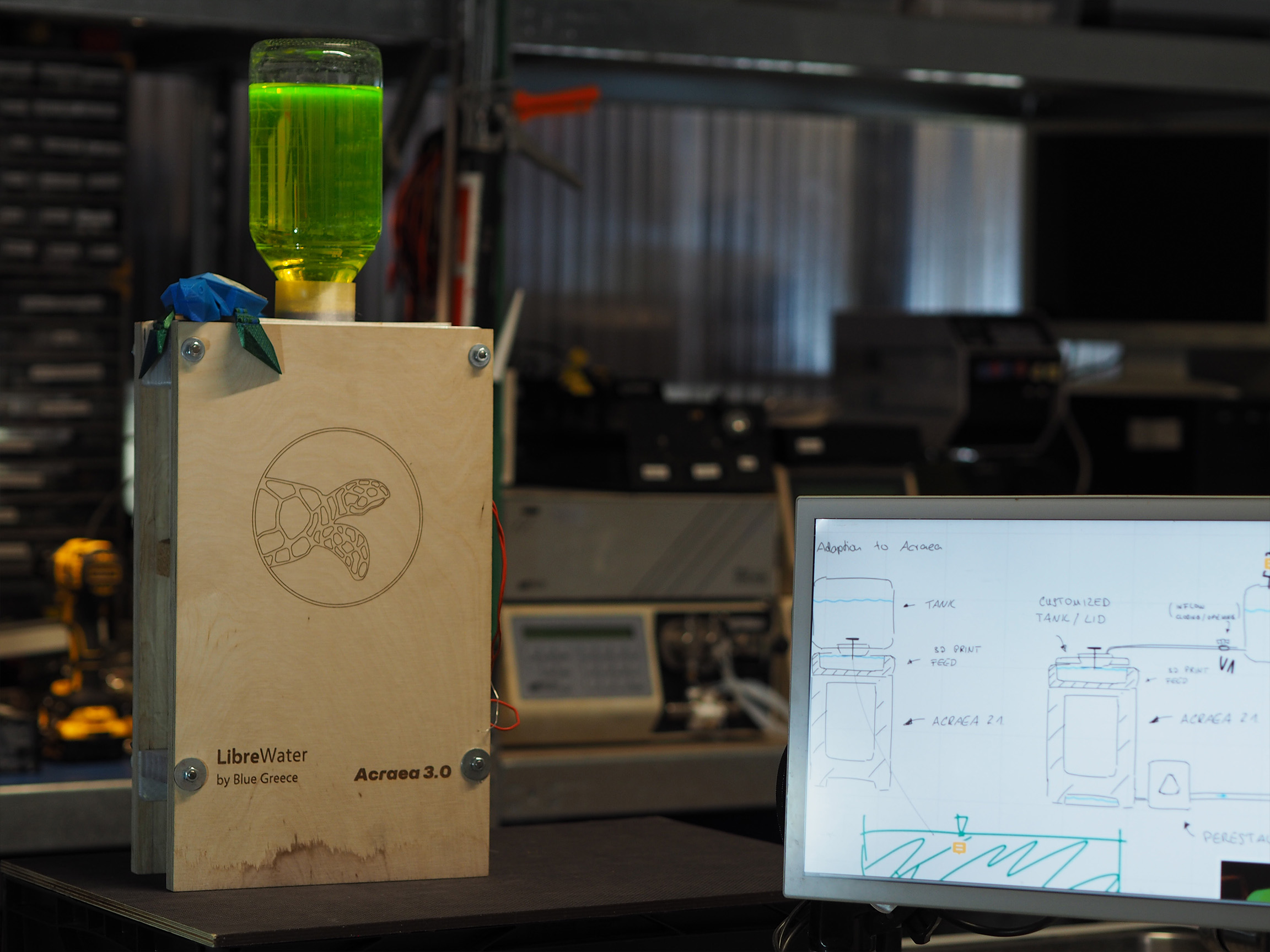

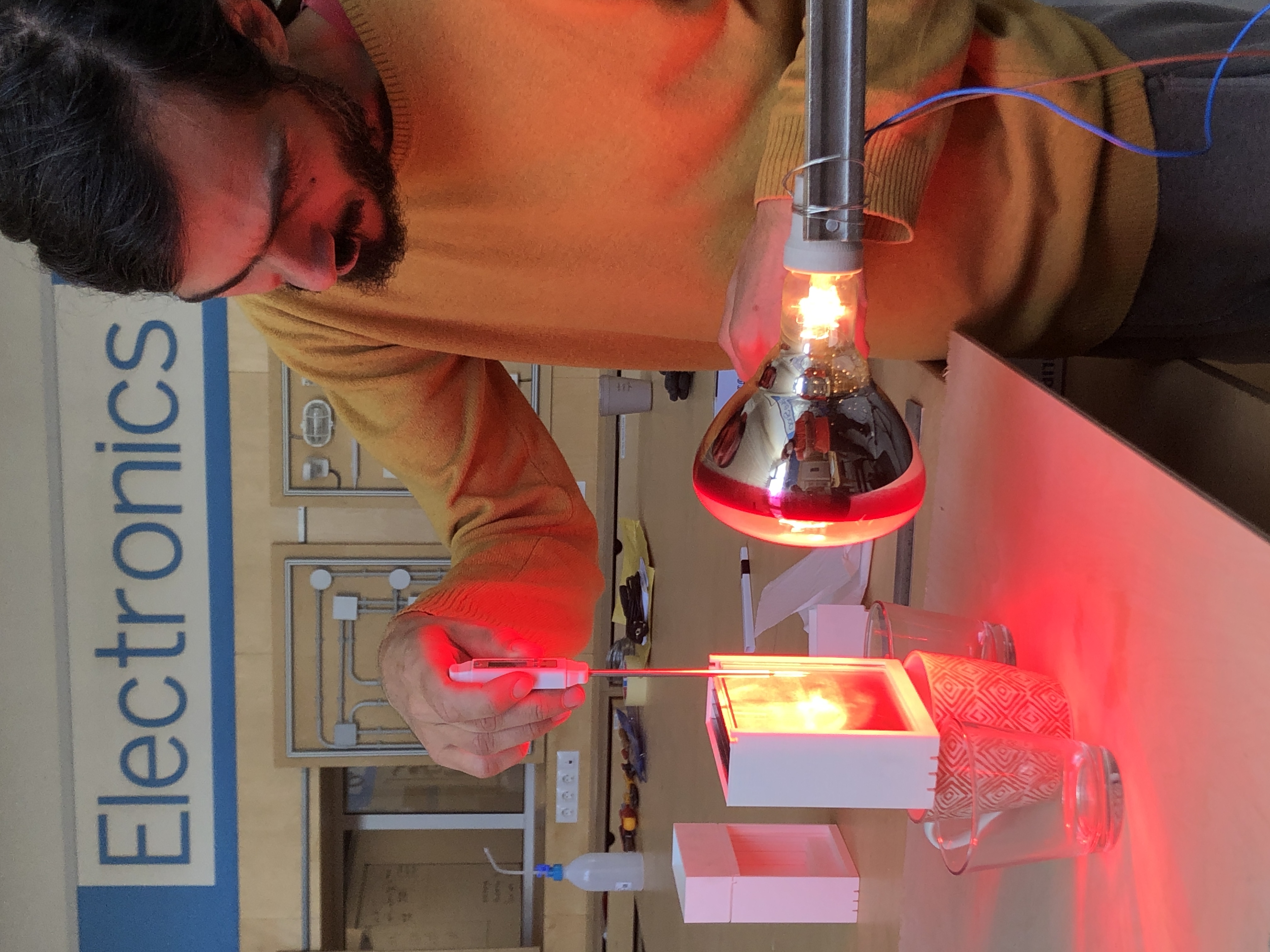

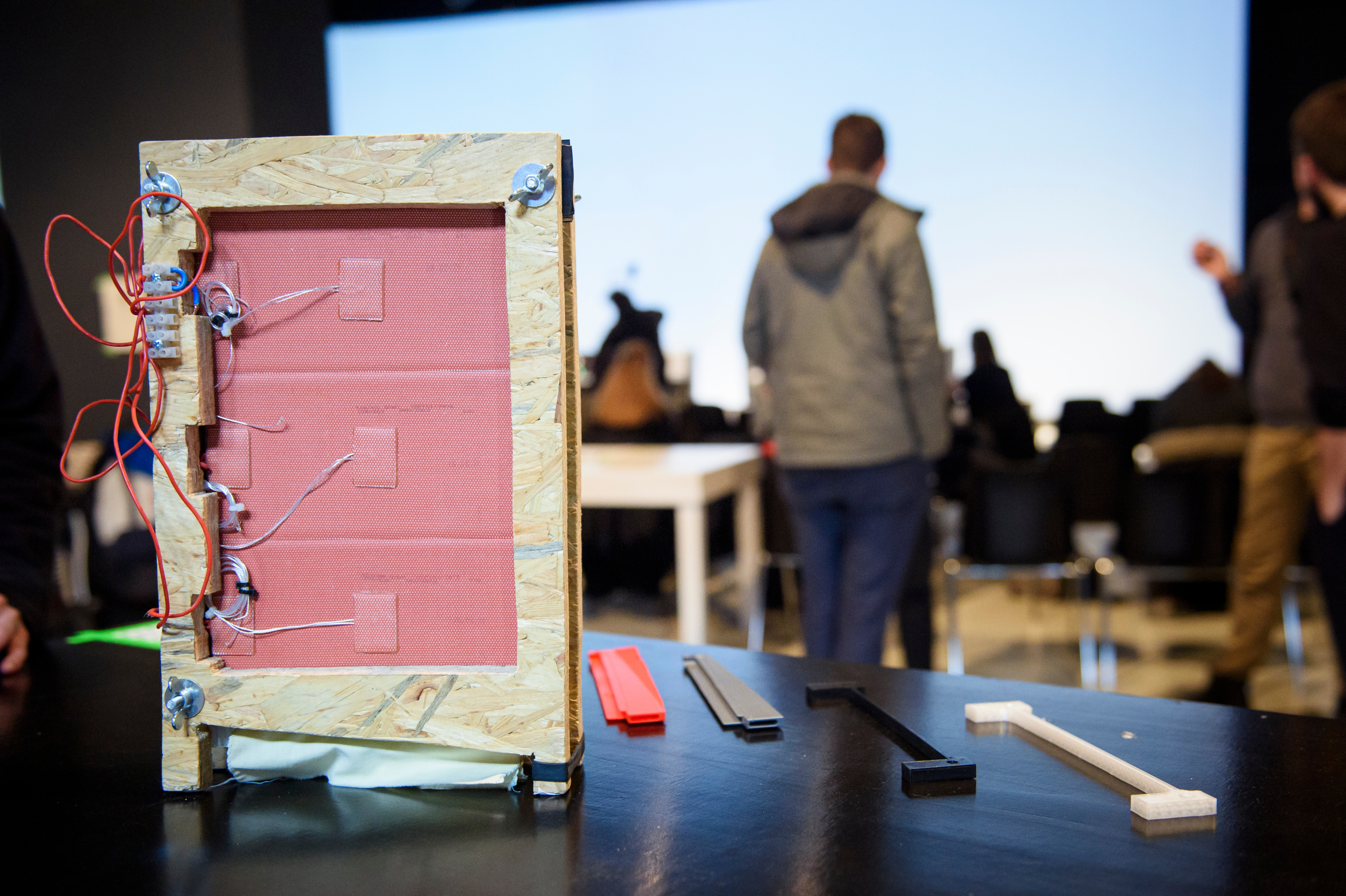

I joined the open source product development (OSPD) project "LibreWater" during my master's thesis. Together, with many contributions, we pushed forward the prototype from a 10x10 cm box towards a prototype for laboratory tests.

The thing about open source design is that it is never finished. It is evolutionary, constantly changing and improving. We are continously working with supporters to improve performance, materials and usability.

Get a glimpse of the journey.

Research

Over the past 60 years, countless scientists and a few entrepreneurs have worked on Solar-Powered Multiple-Effect-Distillation. One of the most recent reviews is from January 2022 by Lim et al. from Korea Institute of Machinery & Materials: Designs and performance analysis of vertical multi-effect diffusion solar distiller: A review - ScienceDirect (OpenAccess)

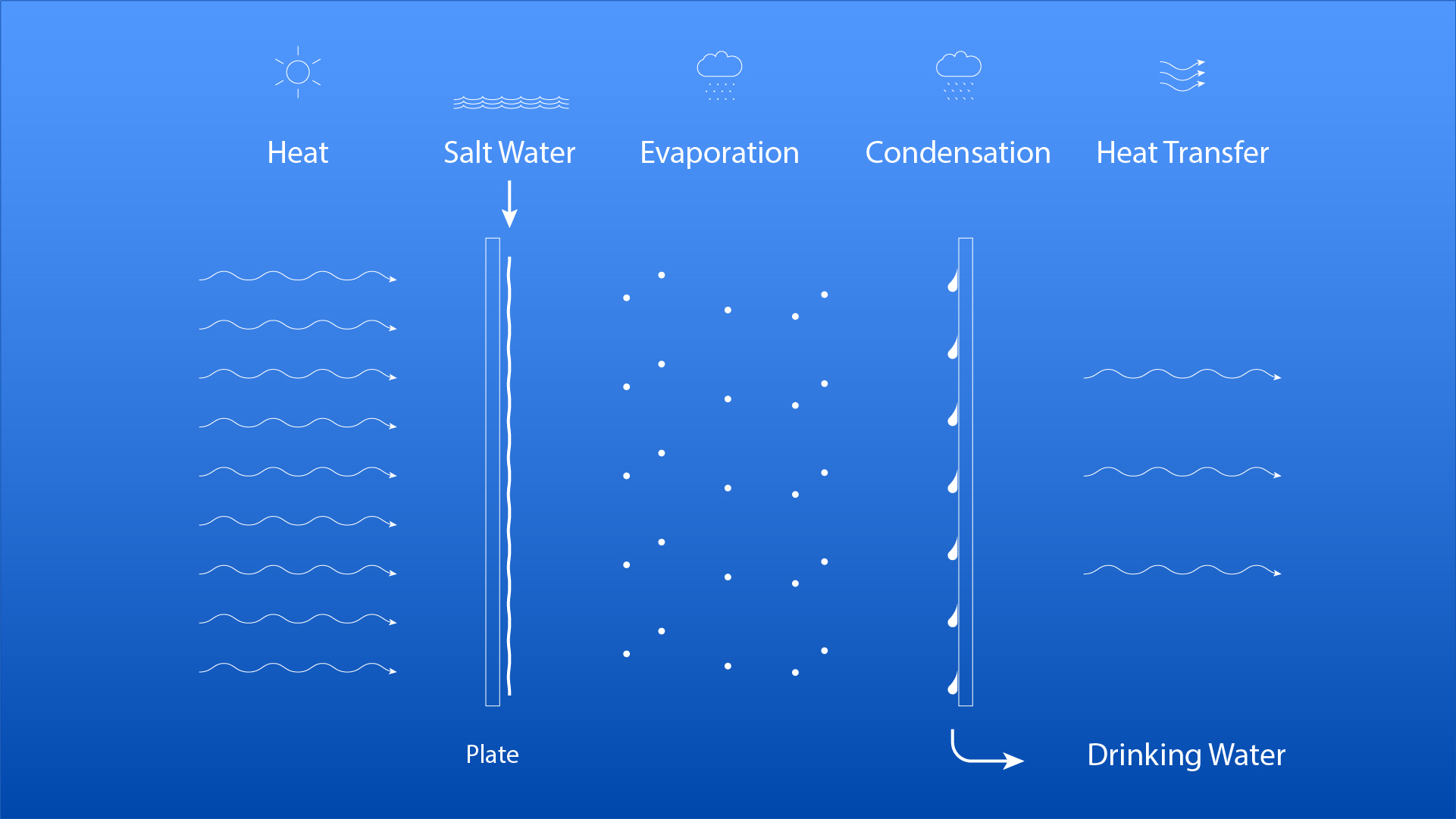

How it works

Inspired by nature, the technology is as simple as rain in a box.

Water is evaporated to clean steam and condensed again on an array of metal plates: Creating highly pure water from almost any water source without the need for special filters. The heat from the condensation process is recovered.

Components

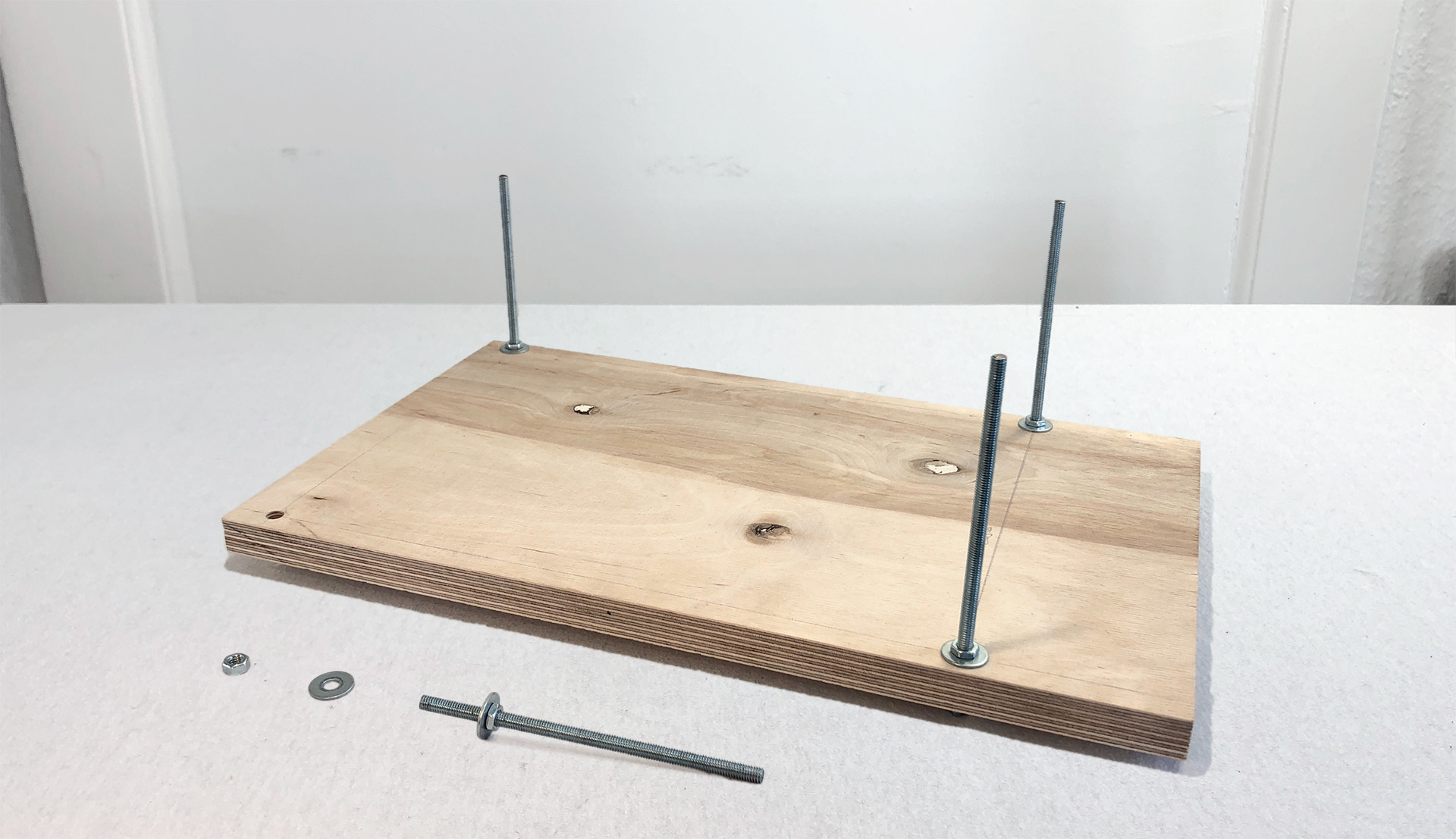

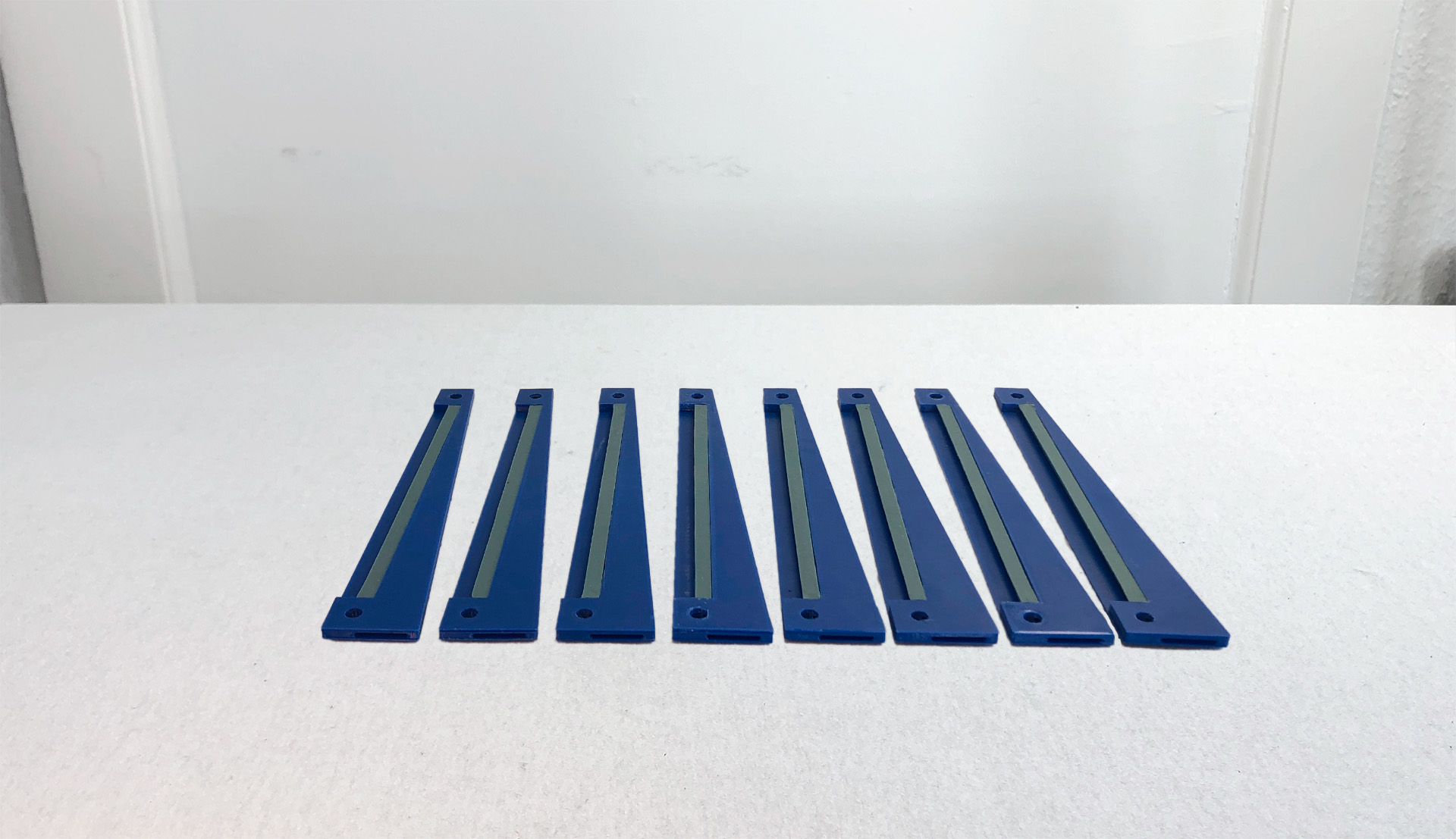

- Casing from recycled platic/wood + standardized threaded rods [image 1, 2]

- Feed - parts 3d printed; PETG [image 3,]

- Drainage - parts 3d printed; PETG [image 4]

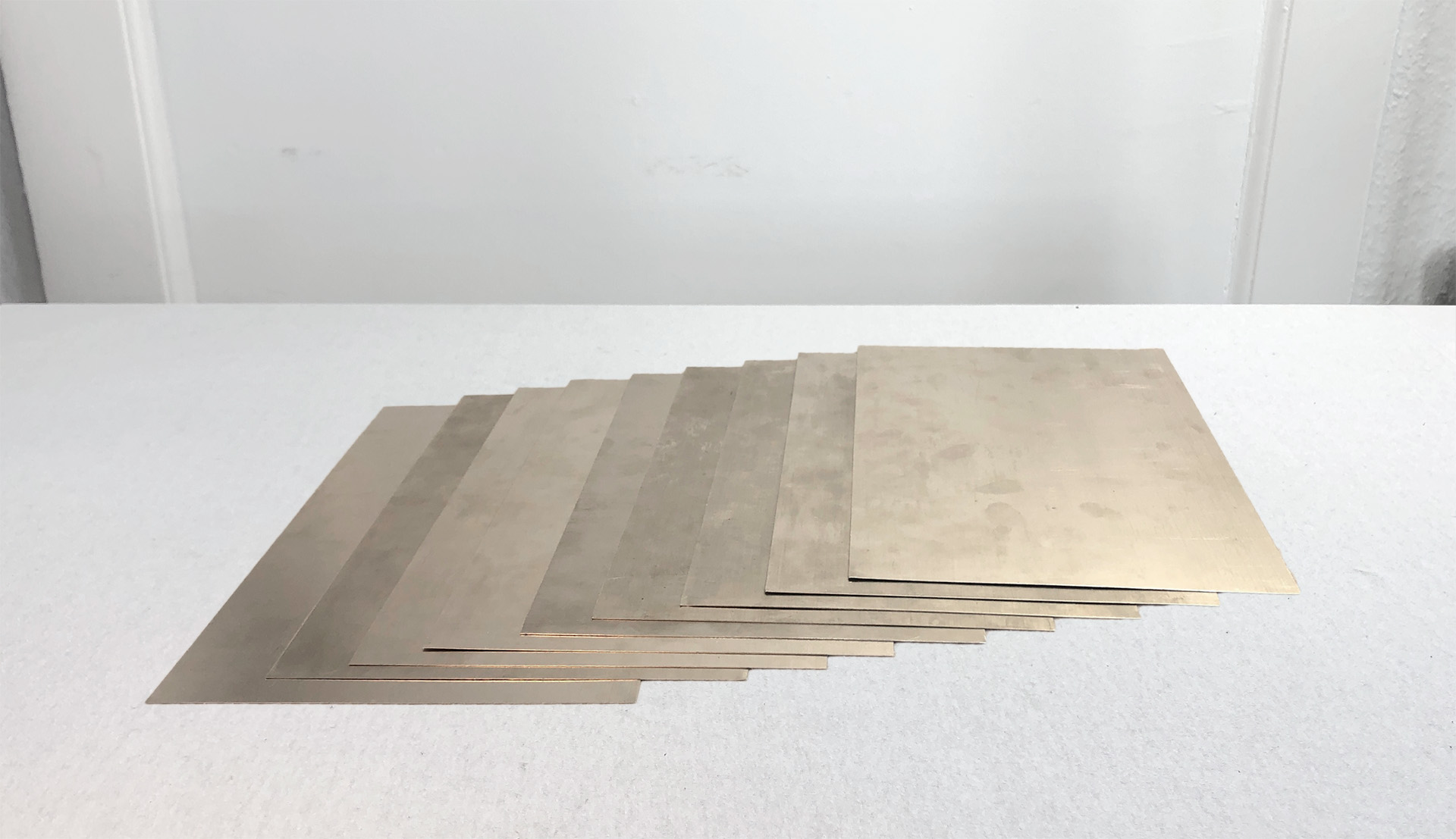

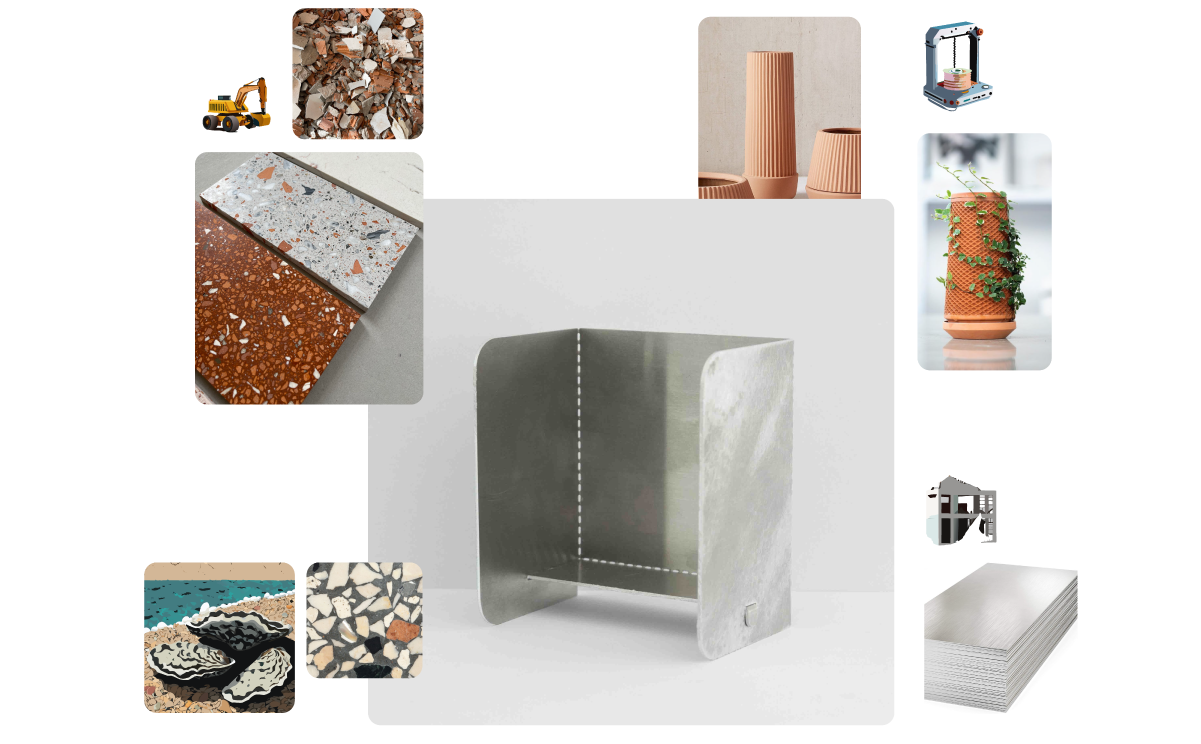

- Plates - metal sheets; currently Aluminium [image 5]

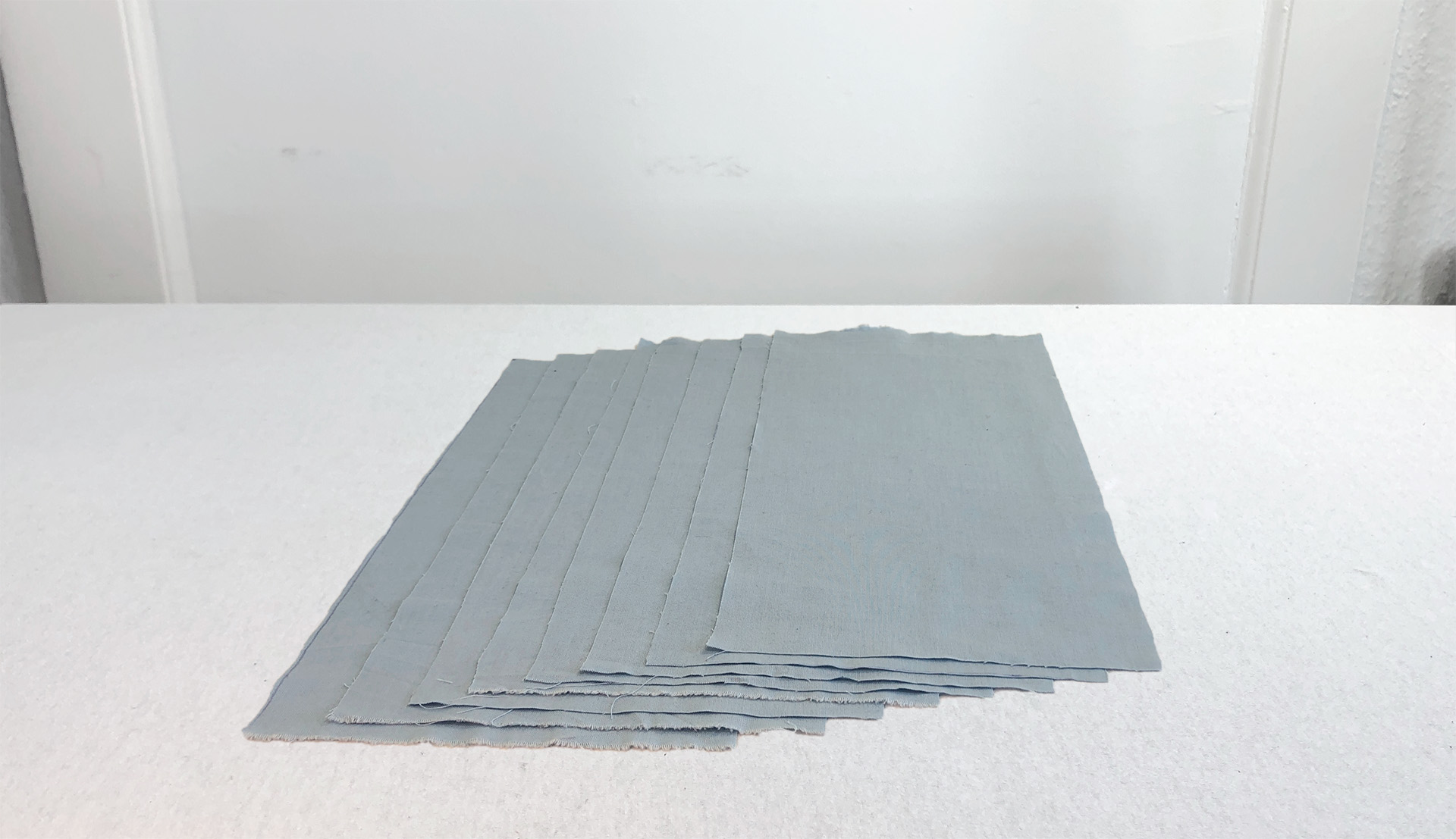

- Wicks - reused textile; cotton [image 6]

To qualify as open source hardware, the DIN SPEC 3105 (2020), specifies the requirements for technical documentation (part 1) and Community-based assessment (part 2).

https://www.beuth.de/en/technical-rule/din-spec-3105-1/324805763

https://www.beuth.de/en/technical-rule/din-spec-3105-2/324805750

Find the repository and full documentation of the project here:

https://codeberg.org/LibreWater/Acraea-Prototype

Assembly

Prototyping in Makerspaces

The great thing about decentralized product development is that work can be done in many places at the same time and only the data is exchanged. #DistributedDesign

I enjoy working on a project in a local makerspace. It creates proximity and sparks the interest of civil society. At the same time, openness enables early contact with potential end users and knowledge exchange.

Co-Creation

OSPD is powered by communities sharing the same values and interests in a product or topic.

LibreWater tackles water scarcity and promotes equitable access to water, creating a purposeful and shared mission for individuals to join forces with like-minded change-makers.

Whats next?

Goals

- Complete monitoring: Collect data on water quality and performance, using the prototype as a permanent test base.

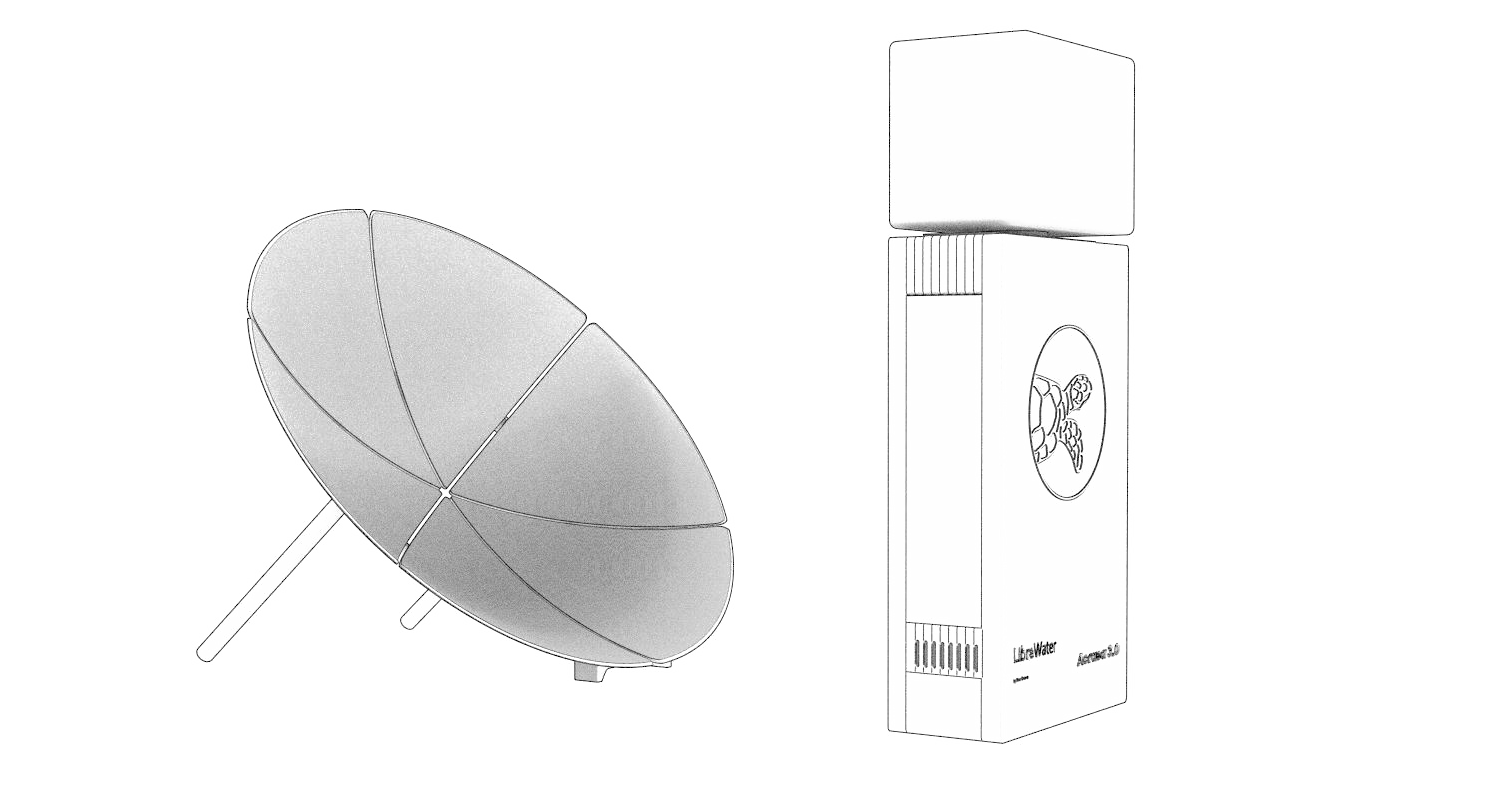

- Solar heating: Implementation of a parabolic mirror (or similar) to concentrate the sun's energy onto the metal plates.

- R&D biomaterials: Testing of materials with a lower environmental impact and the possibility of local sourcing and processing, such as naturally occurring or waste materials.

- From the lab to the field: Identifying relevant stakeholders, like makerspaces, in areas of water scarcity. Jointly adapting the open design to local conditions.